Thanks for getting in touch!

We appreciate you contacting us. One of our colleagues will get back in touch with you soon!

Have a great day!

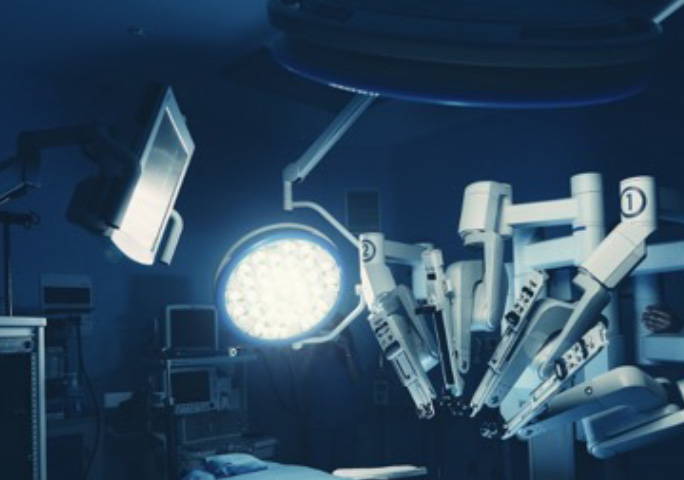

Medical equipment manufacturers spend a great deal of time designing systems and architectures that are robust and employ the appropriate flash technology to ensure broad compatibility while being sensitive to application workload requirements.

Some applications may require larger and faster grades of NAND Flash memory, while other applications don’t need high capacities or fast performance. So the first steps in the design in process are all about how the flash storage memory will be used and what types of files you need to store and process.

Because NAND flash memory is widely available in a variety of form factors and performance & reliability levels, it’s important to partner with a manufacturer like Centon Electronics that can provide a customized solution. The team at Centon Electronics will carefully evaluate your application workload, power management requirements, and environmental conditions (temperature, vibration) to ensure that you have a solution that fits your use case perfectly.

Given that the NAND Flash storage technology being used is mission-critical, the majority of NAND flash storage solutions will require some level of customization to adequately meet workload requirements in real-world use cases.

NAND Flash storage memory has a finite number of P/E cycles, depending on the type of flash used, i.e. SLC, MLC, TLC, QLC and PLC, so the key to providing the correct technology solution is understanding the application workload and where it lies in the spectrum of reads and writes to the media. Some applications will be primarily Read intensive, some may be Write intensive, and some may present a balanced or mixed use case. This will dictate what type of NAND Flash storage is used, and whether or not special considerations must be handled in firmware development to optimize for these application environments.

All of this, coupled with specialized wear leveling techniques, spare cell allocation, LDPC ECC, SMART analysis and E2E data protection will ensure the highest data reliability possible in your given application.

NAND Flash storage can be manufactured to withstand extreme environmental conditions, but in doing so, costs can increase considerably depending on the operating environment of a given application. This is another critical area where Centon Electronics expertise comes into play in determining the correct balance of temperature and vibration resistance required to optimize your solution in both ruggedness and environmental performance.

Medical Equipment Manufacturers will likely have a strong bias towards component control and reliability of their solution. Centon Electronics has a strict manufacturing and procurement process that insures 100% conformance once the product qualification is completed. Explicitly, this means that once the NAND flash, controller, and firmware are approved, the customers BOM is controlled and locked for a defined period based on the needs of the customer and the application.

If due to supply continuity challenges or customer initiated change requests, BOM alterations are required, the original part number will be retired and the new BOM will be numbered and locked again.

Centon's strategic partnerships with leading memory suppliers ensure long-term bill of materials availability and product supply continuity. By implementing this sourcing strategy, Centon Electronics can guarantee longer product life cycles with buffer inventory.

Power interruption is a real possibility in the day to day operation of a given piece of equipment, but becomes more critical when considering the implications for medical equipment and the mission critical data that is stored on this equipment. Client records, medical test results & images and other sensitive information must be protected from unintended power loss.

Centon Electronics NAND Flash solutions go the extra mile to ensure that Power Loss Data Protection is present in all our storage memory solutions, using additional circuitry and capacitors. This gives Centon’s products additional power and the ability to flush the data residing in the DRAM and buffers which ensures data integrity and protects against data corruption in the event of system failure or unexpected power loss.

In medical/health care applications, patient information is vital to care and effective treatment, and there is no margin for error in the safe storage of that data. Centon Electronics is an ISO 9001 and 14001 certified company and strictly follows the established standards as set forth by JEDEC, the SD Association and the CFA.